Understanding Manual Lever Hoists A Comprehensive Overview

Manual lever hoists, often referred to as lever chain hoists, are essential tools in the industries that require lifting and lowering heavy loads with precision and safety. These versatile devices combine mechanical advantage with user-friendly operation, making them suitable for a variety of applications ranging from construction and manufacturing to entertainment and maintenance.

Design and Mechanism

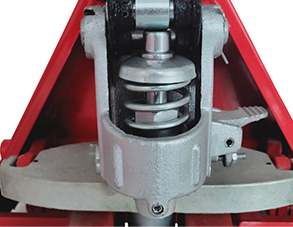

A manual lever hoist consists of several key components a lever arm, a chain or rope, a hook for attaching the load, and a ratchet mechanism. The lever arm, typically made of durable steel, allows the operator to apply force with limited effort, thanks to the mechanical advantage provided by the gear system. As the lever is pulled down, the chain within the hoist is engaged, allowing for the lifting of loads that might otherwise be too heavy to lift manually.

The manual hoist operates on a simple principle of physics by increasing the length of the effort arm—the distance from the fulcrum to where the force is applied—the operator can lift a much heavier load than they could with brute strength alone. This feature makes manual lever hoists particularly advantageous in tight spaces or when power sources are not available.

Applications and Usage

The range of applications for manual lever hoists is extensive. In construction, they are used for lifting heavy materials like steel beams and concrete blocks. In the manufacturing sector, lever hoists facilitate the assembly processes by lifting components into place. Even in the entertainment industry, they are employed to rig and maintain various structures and equipment.

Using a manual lever hoist is straightforward, but proper training is crucial. Operators must be familiar with the device’s components and safe loading practices to avoid accidents. Regular maintenance is also essential to ensure the hoist operates effectively. This includes inspecting the chains for wear, checking the integrity of the hooks, and ensuring the ratchet mechanism works smoothly.

Safety Considerations

Safety is paramount when using manual lever hoists. Operators should always adhere to weight limits specified by the manufacturer to avoid overloading, as this can cause equipment failure or personal injury. It is advisable to use hoists in conjunction with appropriate safety gear, including gloves and helmets, depending on the work environment.

Additionally, users should ensure that the load is properly balanced before lifting. Off-center loads can lead to unexpected shifts, putting the operator and nearby personnel at risk. Always position the hoist and operator in a way that avoids potential hazards, such as pinch points or falling objects.

Advantages of Manual Lever Hoists

One of the primary advantages of manual lever hoists is their portability. Unlike electric hoists, they do not require a power source, making them ideal for work in remote locations or during power outages. Their relative simplicity also means they are less prone to mechanical failures and easier to repair when necessary.

Furthermore, manual lever hoists are generally more cost-effective than their electric counterparts, making them accessible for small businesses and independent contractors. They require minimal maintenance and can offer longevity if properly cared for.

Conclusion

In conclusion, manual lever hoists are indispensable tools across various industries. Their ability to lift heavy loads safely and efficiently, coupled with ease of use and low maintenance costs, makes them a preferred choice for many professionals. Understanding how to operate these devices safely and effectively can significantly enhance workflow and ensure that projects are completed smoothly and without incident. Whether you are a seasoned operator or new to the field, investing in a quality lever hoist can pay dividends in terms of safety and productivity.