Understanding Pallet Truck Design Essential Features and Innovations

Pallet trucks, also known as pallet jacks, are indispensable equipment in warehouses and distribution centers. They facilitate the efficient movement of goods, allowing for streamlined operations and improved productivity. The design of pallet trucks has evolved significantly over the years, integrating advanced features and materials that enhance their functionality. This article delves into the essential aspects of pallet truck design and the innovations that define the modern equipment.

At the core of any pallet truck is its structural design, which typically features three primary components the forks, the hydraulic lifting mechanism, and the handle. The forks are designed to slip under a pallet and lift it off the ground, while the hydraulic system allows for the easy elevation of loads. Modern pallet trucks often utilize a double-acting hydraulic pump, enabling smoother lifting and lowering actions. This not only improves efficiency but also increases safety by reducing the risk of dropped loads.

One of the critical design considerations is the weight capacity of the pallet truck. Standard pallet jacks can typically handle loads ranging from 2,500 to 5,500 pounds. However, specialized designs exist for heavier loads, boasting capacities of up to 10,000 pounds. Engineers must carefully analyze the materials used in construction to ensure that the truck can support these weights without compromising safety or performance. Common materials include high-strength steel for durability and lightweight aluminum for more maneuverability.

Another crucial innovation in pallet truck design is the incorporation of ergonomics. The handle design has undergone significant improvements, allowing for a more comfortable grip and angle of operation. Some pallet trucks now feature adjustable handles that can accommodate different operator heights, reducing the risk of strain and injuries during use. Additionally, many models come with ergonomic support features, such as cushioned grips and controls positioned for easy access, which enhance user comfort.

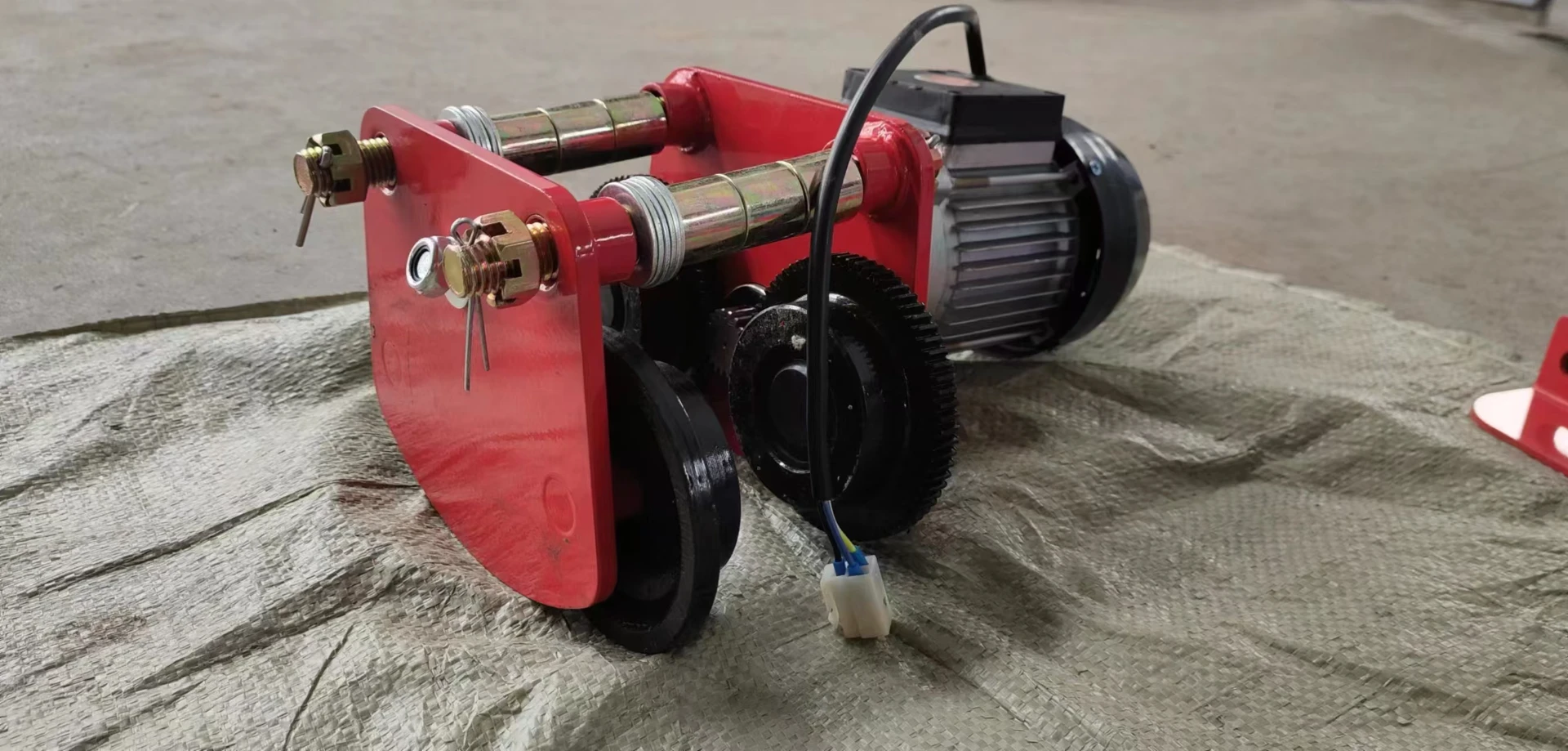

The design of the wheels and castors also plays a crucial role in overall performance. Pallet trucks equipped with polyurethane or nylon wheels offer better traction and maneuverability on various surfaces. Innovations have led to the development of swivel wheels that allow for tight turning radiuses, making it easier to navigate crowded warehouses. Furthermore, some advanced models include features such as powered movement systems, which reduce manual effort, especially for heavy loads.

Safety is another paramount consideration in the design of modern pallet trucks. Features such as automatic braking systems, load notifications, and enhanced visibility through reflective components are becoming standard. These additions help prevent accidents and injuries within busy working environments. Moreover, designs that consider the stability of the load during movement are vital; this includes wider fork bases and sophisticated weight distribution systems.

In conclusion, the design of pallet trucks continues to evolve, incorporating advanced materials, ergonomic principles, and safety features that cater to the diverse needs of modern warehousing and logistics. By focusing on these aspects, manufacturers can create more efficient, user-friendly, and safer equipment. As industries continue to demand higher efficiency and productivity, innovations in pallet truck design will likely play a pivotal role in shaping the future of material handling.