Mini electric hoists with trolleys have revolutionized the way industries approach material handling, offering a seamless blend of convenience, safety, and efficiency. As an expert in the field of industrial equipment, I have witnessed firsthand the transformative power these compact devices bring to the table, backed by years of innovation and refinement.

The mini electric hoist, paired with a trolley, represents a leap forward in lifting technology, making it an essential component in factories, warehouses, and construction sites. Unlike traditional manual hoists, the electric variant significantly reduces human exertion, allowing for quick and effortless lifting of various weights. This not only boosts productivity but also enhances workplace safety—an aspect critical to any industrial operation.

In terms of expertise, the engineering behind mini electric hoists is impeccable. They are designed to accommodate a range of loads, usually between 100kg to 1000kg, meeting the diverse needs of different sectors. The inclusion of overload protection and emergency stop functions further underscores their safety credentials, proving that user welfare is paramount. Furthermore, these hoists are constructed using high-quality materials such as hardened steel and aluminum, ensuring durability and long-term reliability.

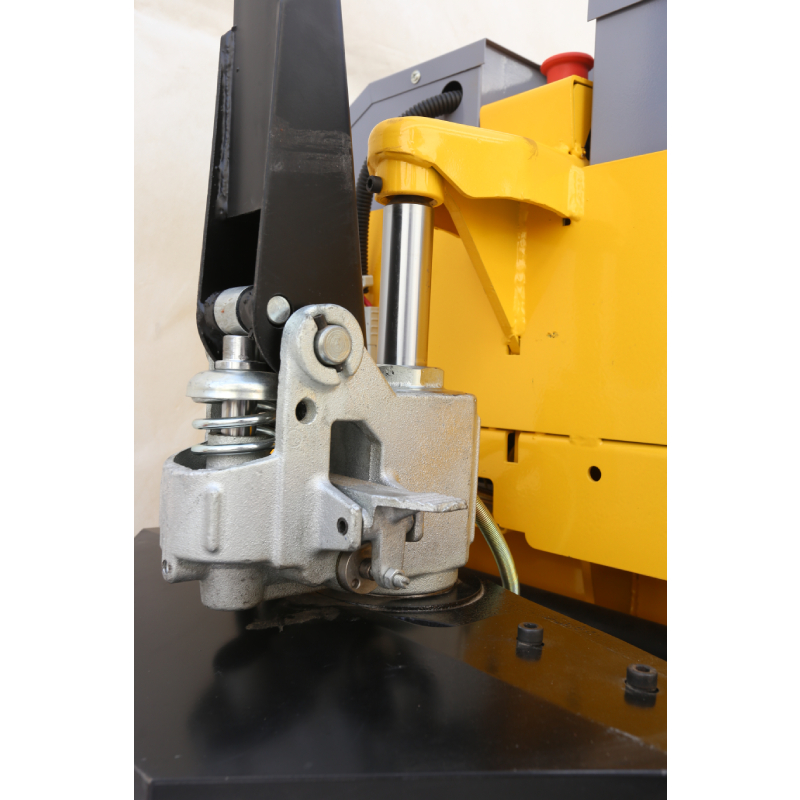

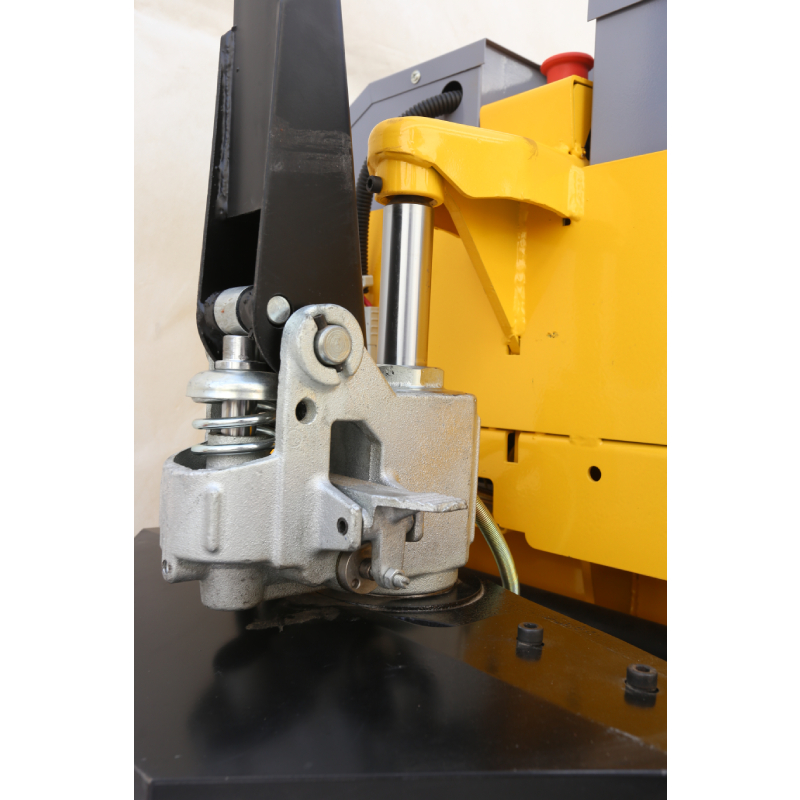

One of the standout features is the integration of the trolley system with the hoist. This fusion allows for horizontal movement across a multitude of beam types, providing unmatched mobility. The trolley enables users to position loads with pinpoint accuracy, a crucial requirement when handling delicate or bulky items. The experience of utilizing such a device is akin to having an extra pair of highly coordinated hands, dramatically shifting the dynamics of heavy-duty tasks.

The element of trustworthiness cannot be overstated when dealing with mini electric hoists with trolleys. Reputable manufacturers subject their products to rigorous testing under varied conditions to ensure they meet global safety standards, such as the European CE marking and the US-based ASME standards. This dedication to quality assurance instills confidence in the user, who can rely on the equipment to perform under pressure without unexpected failures.

mini electric hoist with trolley

Adding to their authority in the field, these hoists often come with comprehensive user manuals and support services, facilitating ease of installation and operation. In some instances, manufacturers provide specialized training sessions, thereby empowering users to leverage the full potential of their equipment safely and effectively. Such initiatives are testament to their commitment to user education and safety, reinforcing their position as leaders in the material handling industry.

The adoption of mini electric hoists with trolleys also aligns with broader industrial trends towards automation and efficiency. As industries continue to digitize and streamline operations, the role of these devices becomes increasingly central. They enable companies to optimize workflows, reduce downtime, and maintain competitive edge in an ever-evolving marketplace.

Environmental considerations have not been overlooked either. Modern electric hoists are designed with energy efficiency in mind, consuming less power without sacrificing performance. This not only reduces operational costs but also complements corporate sustainability goals, a vital aspect in today’s business environment.

In conclusion, mini electric hoists with trolleys embody the perfect synergy of innovation, reliability, and functionality. The continuous advancements and commitment to user-centric design have not only cemented their place in the industry but have also laid the foundation for future technological breakthroughs. For businesses looking to enhance their operational capabilities while prioritizing safety and efficiency, investing in these hoists is undeniably a step in the right direction.