Understanding Pallet Power Jacks A Key Tool in Warehouse Operations

In the fast-paced world of logistics and warehousing, efficiency and reliability are paramount. One essential piece of equipment that plays a critical role in these operations is the pallet power jack, also known as the electric pallet jack or powered pallet truck. This innovative device has revolutionized how goods are transported within warehouses, improving productivity and reducing manual labor requirements.

What is a Pallet Power Jack?

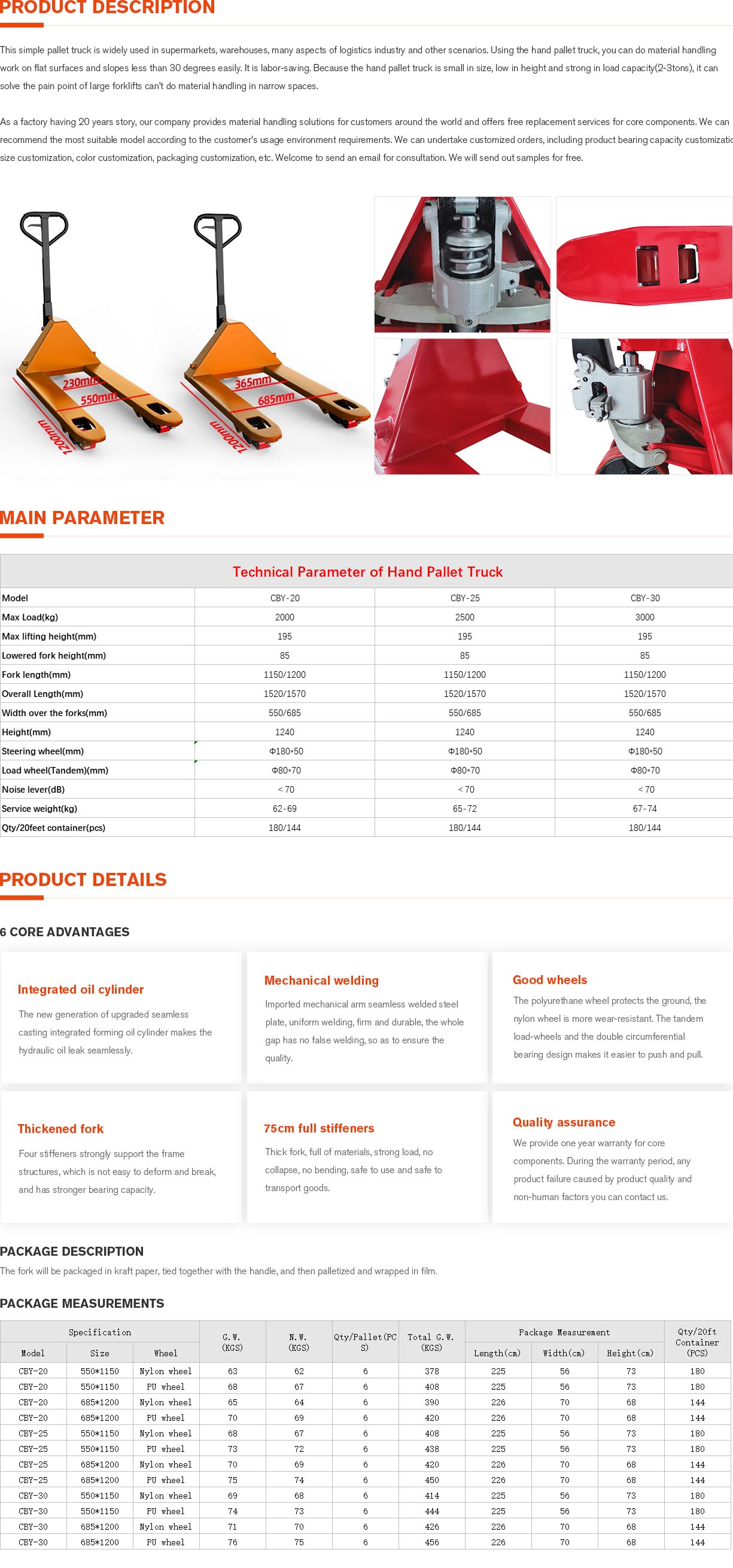

A pallet power jack is a motorized device designed to lift and move palletized loads. It operates by using electric power to drive the wheels, making it easier for operators to transport heavy items over short distances. Unlike traditional hand-operated pallet jacks, which require significant physical strength to maneuver, electric pallet jacks can move heavier loads with minimal effort.

These machines are equipped with forks that can be inserted under a pallet, allowing an operator to lift the load off the ground. Depending on the model, pallet power jacks can handle weights ranging from 3,000 to 6,000 pounds or more, making them versatile tools for various industries, including retail, manufacturing, and food service.

Benefits of Using Pallet Power Jacks

1. Increased Efficiency One of the most significant advantages of using a pallet power jack is the increase in operational efficiency. Electric pallet jacks allow workers to move materials quickly without tiring easily. This speed translates to shorter cycle times in warehouses, enabling companies to process and ship orders faster.

2. Reduced Labor Strain Handling heavy pallets manually can lead to fatigue and workplace injuries. Pallet power jacks alleviate this physical strain, allowing employees to focus on other tasks without the risk of developing musculoskeletal injuries. This contributes to a safer workplace environment, reducing potential downtime due to worker injuries.

3. Ease of Use Most pallet power jacks are designed with user-friendly controls, making them easy for operators to learn and use effectively. With minimal training, employees can become proficient, allowing businesses to quickly adapt to workforce changes without significant training costs.

4. Improved Maneuverability Electric pallet jacks are typically more maneuverable than their manual counterparts. They are built with compact designs that make it easier to navigate tight spaces, such as narrow aisles between shelves. This capability maximizes storage efficiency and improves overall warehouse layout and design.

5. Low Operating Costs While the initial investment in a pallet power jack may be higher than that of a manual jack, the long-term operational costs can be lower. Electric pallet jacks require less maintenance, and their efficiency can lead to decreased labor costs, ultimately providing a good return on investment.

Conclusion

Pallet power jacks are indispensable tools in modern warehouse operations, enhancing efficiency and safety while reducing labor costs. As the logistics landscape continues to evolve with advancements in technology, the adoption of electric pallet jacks is likely to increase. Companies that invest in these machines will not only improve their operational capabilities but also create a safer and more productive work environment. Overall, the pallet power jack exemplifies how innovation can simplify complex tasks in busy warehouse settings, reflecting on the importance of investing in the right tools for success in the logistics industry.