Understanding the Hydraulic Pallet Jack A Workhorse in Material Handling

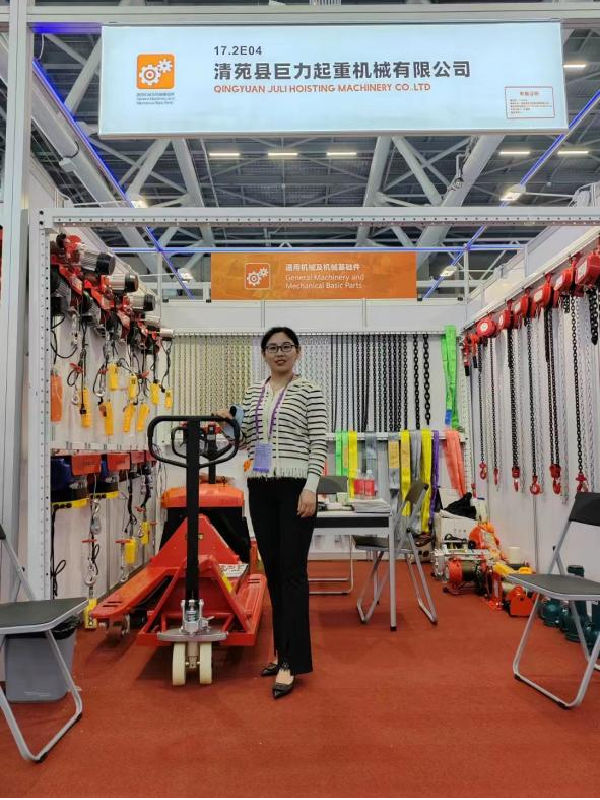

A hydraulic pallet jack, often referred to as a walkie stacker or semi-electric pallet truck, is an indispensable tool in the world of material handling. It's a simple yet powerful device that has revolutionized the way goods are lifted, moved, and stacked in warehouses, distribution centers, and retail stores.

The core mechanism of a hydraulic pallet jack lies in its hydraulic system, a principle derived from Pascal's Law which states that pressure applied at any point in a confined incompressible fluid is transmitted equally in all directions. In the context of a pallet jack, this means that a small force exerted on a small piston can lift a much larger load on a larger piston due to the hydraulic fluid's incompressibility.

The basic design of a hydraulic pallet jack consists of a handle, two forks, a pump, a hydraulic cylinder, and a lifting mechanism. The operator pumps the handle up and down, creating a vacuum that forces the hydraulic fluid from the reservoir into the cylinder. This action raises the forks, lifting the loaded pallet off the ground. To lower the load, the valve is opened, allowing the fluid to flow back into the reservoir, and the weight of the load forces the larger piston down.

One of the key advantages of a hydraulic pallet jack is its simplicity and ease of operation. Unlike full-sized forklifts, they require minimal training and certification to use, making them an ideal solution for smaller operations or as a backup for larger equipment. They are also highly maneuverable, capable of navigating narrow aisles and tight spaces, enhancing efficiency in warehouse operations They are also highly maneuverable, capable of navigating narrow aisles and tight spaces, enhancing efficiency in warehouse operations

They are also highly maneuverable, capable of navigating narrow aisles and tight spaces, enhancing efficiency in warehouse operations They are also highly maneuverable, capable of navigating narrow aisles and tight spaces, enhancing efficiency in warehouse operations

hydraulic pallet jack

hydraulic pallet jack.

Moreover, hydraulic pallet jacks are cost-effective compared to electric or motorized alternatives. They don't need fuel or electricity, reducing operational costs and environmental impact. However, they may not be suitable for heavy-duty lifting or long-distance transport, where motorized forklifts would be more appropriate.

Maintenance of a hydraulic pallet jack is relatively straightforward. Regular checks on the hydraulic fluid level, the condition of the hoses and seals, and ensuring the pump and lifting mechanism are clean and lubricated can prevent many common issues. Prompt repairs for leaks or worn parts can extend the lifespan of the equipment significantly.

In conclusion, the hydraulic pallet jack is a workhorse in the logistics industry, offering a practical, efficient, and cost-effective solution for moving and stacking palletized goods. Its hydraulic system, combined with its compact design, makes it a versatile tool for various material handling tasks. Despite its simplicity, it plays a vital role in keeping supply chains moving smoothly, highlighting the power of hydraulic engineering in everyday operations.

They are also highly maneuverable, capable of navigating narrow aisles and tight spaces, enhancing efficiency in warehouse operations They are also highly maneuverable, capable of navigating narrow aisles and tight spaces, enhancing efficiency in warehouse operations

They are also highly maneuverable, capable of navigating narrow aisles and tight spaces, enhancing efficiency in warehouse operations They are also highly maneuverable, capable of navigating narrow aisles and tight spaces, enhancing efficiency in warehouse operations hydraulic pallet jack.

Moreover, hydraulic pallet jacks are cost-effective compared to electric or motorized alternatives. They don't need fuel or electricity, reducing operational costs and environmental impact. However, they may not be suitable for heavy-duty lifting or long-distance transport, where motorized forklifts would be more appropriate.

Maintenance of a hydraulic pallet jack is relatively straightforward. Regular checks on the hydraulic fluid level, the condition of the hoses and seals, and ensuring the pump and lifting mechanism are clean and lubricated can prevent many common issues. Prompt repairs for leaks or worn parts can extend the lifespan of the equipment significantly.

In conclusion, the hydraulic pallet jack is a workhorse in the logistics industry, offering a practical, efficient, and cost-effective solution for moving and stacking palletized goods. Its hydraulic system, combined with its compact design, makes it a versatile tool for various material handling tasks. Despite its simplicity, it plays a vital role in keeping supply chains moving smoothly, highlighting the power of hydraulic engineering in everyday operations.

hydraulic pallet jack.

Moreover, hydraulic pallet jacks are cost-effective compared to electric or motorized alternatives. They don't need fuel or electricity, reducing operational costs and environmental impact. However, they may not be suitable for heavy-duty lifting or long-distance transport, where motorized forklifts would be more appropriate.

Maintenance of a hydraulic pallet jack is relatively straightforward. Regular checks on the hydraulic fluid level, the condition of the hoses and seals, and ensuring the pump and lifting mechanism are clean and lubricated can prevent many common issues. Prompt repairs for leaks or worn parts can extend the lifespan of the equipment significantly.

In conclusion, the hydraulic pallet jack is a workhorse in the logistics industry, offering a practical, efficient, and cost-effective solution for moving and stacking palletized goods. Its hydraulic system, combined with its compact design, makes it a versatile tool for various material handling tasks. Despite its simplicity, it plays a vital role in keeping supply chains moving smoothly, highlighting the power of hydraulic engineering in everyday operations.