Understanding Hand Chain Blocks A Comprehensive Overview

Hand chain blocks, often referred to as chain hoists, are essential tools in lifting operations across various industries. These mechanical devices allow for the safe elevation, lowering, and positioning of heavy loads, making them indispensable in construction sites, warehouses, and manufacturing plants. In this article, we will explore the components, operation, applications, advantages, and safety considerations associated with hand chain blocks.

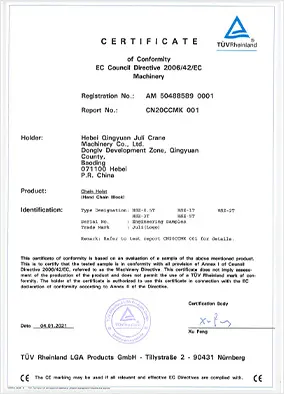

What Is a Hand Chain Block?

A hand chain block is a manual lifting device that uses a chain and pulley system to lift heavy objects. Typically composed of a few key components, the basic structure includes a chain hoist, a lifting chain, a hand chain, and a hook for attaching the load. The operation of a hand chain block relies on mechanical advantage, enabling a user to lift significantly heavier objects than could be managed with sheer physical strength alone.

Components of a Hand Chain Block

1. Load Chain This is the chain that wraps around the gear wheels inside the hoist. When pulled by the hand chain, it engages with the lifting mechanism to hoist the load. 2. Hand Chain The hand chain is what the operator pulls to lift the load. It provides the mechanical advantage needed to elevate the load efficiently. 3. Gears and Ratchets These are the mechanical components that convert the force applied on the hand chain into lifting power. When the hand chain is pulled, the gears rotate, moving the load chain either upwards or downwards. 4. Hook The sturdy hook at the end of the load chain is designed to hold the load securely during lifting. 5. Frame The frame supports the entire system and is typically constructed of robust materials to ensure stability and durability.

Operation of a Hand Chain Block

Operating a hand chain block is relatively straightforward. The user starts by securing the hook to the load they wish to lift. Once properly attached, the operator pulls on the hand chain, which, in turn, causes the load chain to rise, lifting the attached load. The mechanical advantage allows for significant weight being lifted with minimal effort, making it user-friendly.

To lower the load, the operator releases the tension on the hand chain carefully while controlling the descent. This precise manipulation allows for safe positioning of the load, either onto a surface or into a specific area.

Applications of Hand Chain Blocks

Hand chain blocks are used in various scenarios, including

- Construction Sites They are essential for lifting construction materials, beams, and heavy machinery. - Warehousing In storage facilities, hand chain blocks assist in moving products onto shelves or loading docks. - Manufacturing Industries leverage these tools for assembly processes where heavy equipment must be repositioned. - Theater and Stage Production Hand chain blocks are often used to lift stage sets and lighting rigs.

Advantages of Hand Chain Blocks

1. Cost-Effective Compared to electric hoists, hand chain blocks are generally more affordable, making them accessible for small businesses and individual users. 2. Portability Their lightweight construction makes them easy to transport and use in various locations. 3. Minimal Maintenance Hand chain blocks require very little maintenance, which reduces downtime and operational costs. 4. User Control Operators have full control over the lifting and lowering processes, allowing for precision handling of loads.

Safety Considerations

While hand chain blocks are valuable tools, safety should always be a priority. Operators must be trained and aware of the following safety practices

- Inspect Regularly Check for wear and tear, especially on chains and hooks, before each use. - Follow Weight Limits Adhere to the manufacturer's specifications regarding the maximum load capacity to prevent accidents. - Use Proper Techniques Employ correct lifting techniques to reduce the risk of injury. - Avoid Load Swinging Ensure the load is stable and avoid sudden movements that could cause swinging, which is a safety hazard.

Conclusion

Hand chain blocks are a vital component in the lifting arsenal of many industries. Their simple yet effective design offers significant lifting capabilities without the need for electrical power. By understanding their components, operation, and applications, as well as adhering to safety practices, users can ensure safe and efficient lifting operations in their respective fields. Whether in construction, warehousing, or manufacturing, hand chain blocks continue to play a crucial role in facilitating heavy lifting tasks across various environments.