Understanding Hand Chain Blocks A Comprehensive Guide

Hand chain blocks, also known as hand-operated hoists, are essential tools in various industries for lifting heavy loads. These devices are particularly popular due to their simplicity, reliability, and ease of use. In this article, we will delve into what hand chain blocks are, how they work, their applications, and safety measures that should be considered when using them.

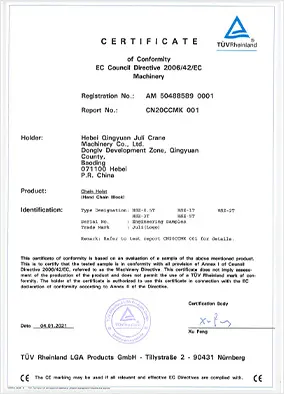

What is a Hand Chain Block?

A hand chain block is a type of hoisting device that uses a chain and a set of gears to lift or lower heavy objects. It typically consists of a hand chain for manual operation, a lifting chain, a hook for securing the load, and a housing that contains the gearing mechanism. The beauty of a hand chain block lies in its design it converts human effort into mechanical advantage, allowing users to lift significantly heavy items without needing extensive machinery.

How Does It Work?

The operation of a hand chain block is straightforward. It incorporates a system of pulleys and gears to achieve mechanical advantage. When the operator pulls on the hand chain, it engages the gearing system, which then lifts the load attached to the lifting chain. The mechanical setup ensures that minimal physical effort translates into substantial lifting capability. For instance, a hand chain block rated for 1 ton can easily lift loads that weigh up to 1 ton with a simple pull of the chain.

The mechanism includes safety features such as a ratchet and pawl, which prevents the load from falling if the hand chain is released. This is a critical safety feature that makes hand chain blocks reliable in various settings, including construction sites, warehouses, and garages.

Applications

Hand chain blocks have a wide range of applications across various industries

. They are commonly used in

1. Construction For lifting materials and equipment to elevated heights with ease. 2. Warehousing To move heavy items, such as pallets or large cartons, within storage facilities. 3. Automotive In garages for lifting engines or other heavy vehicle components. 4. Marine On boats and in docks for moving cargo and maintaining equipment.

Their portability and ease of setup make hand chain blocks an excellent choice for numerous lifting tasks, especially where electricity or complex machinery is not practical.

Advantages of Hand Chain Blocks

1. Manual Operation They do not require electricity, making them useful in remote locations. 2. Cost-Effective Generally less expensive than powered hoists, they provide a simple solution for lifting needs. 3. Portable Lightweight and easy to transport, they can be used in various settings with minimal hassle. 4. Low Maintenance With fewer moving parts compared to powered hoists, hand chain blocks require less upkeep.

Safety Considerations

While hand chain blocks are effective lifting tools, safety should never be compromised. Here are some essential safety precautions to follow

1. Inspect Before Use Always check the condition of the hand chain block before use, looking for any signs of wear or damage. 2. Check Load Capacity Only lift loads within the rated capacity of the block to prevent accidents. 3. Secure the Load Ensure that the load is properly secured with hooks or slings to prevent slippage. 4. Use Proper Technique Keep your body clear of the load while operating the hand chain block and ensure that the area is free of obstructions. 5. Training Operators should be adequately trained in using hand chain blocks, understanding both the operation and inherent risks involved.

Conclusion

Hand chain blocks are invaluable tools for lifting heavy objects across various industries. Their simple design, combined with effective mechanical advantages, makes them an essential asset in many lifting applications. However, it is critical to prioritize safety and ensure proper usage to mitigate risks. Understanding the functionality, applications, and safety protocols associated with hand chain blocks will help operators effectively manage their lifting tasks while maintaining a safe working environment.