Navigating the busy lanes of a bustling warehouse or a crowded grocery storage room becomes effortless with a full-powered pallet jack. As industries continue to escalate their production capacities, the transition from manual to full-powered pallet jacks is not only a smart move but an essential upgrade for maintaining efficiency, safety, and productivity.

Experience in juggling heavy loads in compact spaces reveals that full-powered pallet jacks are game-changers. Unlike their manual counterparts, these machines diminish the physical strain on warehouse staff, effectively diminishing potential injury risks and boosting morale. With intuitive controls and smooth maneuverability, operators find them incredibly user-friendly, drastically reducing the learning curve associated with warehouse machinery.

Delving deeper into their expertise, full power pallet jacks stand out with their robust motor systems and advanced battery technologies. The latest models feature lithium-ion batteries, known for their swift recharging times and remarkable energy efficiencies compared to traditional lead-acid variants. This development ensures longer operational hours with minimal downtime, a critical factor in environments where time equates to money. The implementation of regenerative braking systems not only contributes to energy conservation but enhances control during operation, offering precision when handling fragile or hazardous loads.

From an authoritative standpoint, the integration of advanced technology like onboard diagnostics is reshaping maintenance protocols. Real-time data collection and analysis empower technicians to conduct proactive maintenance, thereby reducing the frequency of breakdowns and extending the lifespan of the pallet jack. Manufacturers have also begun incorporating IoT capabilities, allowing fleet managers to monitor equipment remotely. This data-driven approach not only optimizes performance but aligns seamlessly with modern lean management practices.

full powered pallet jack

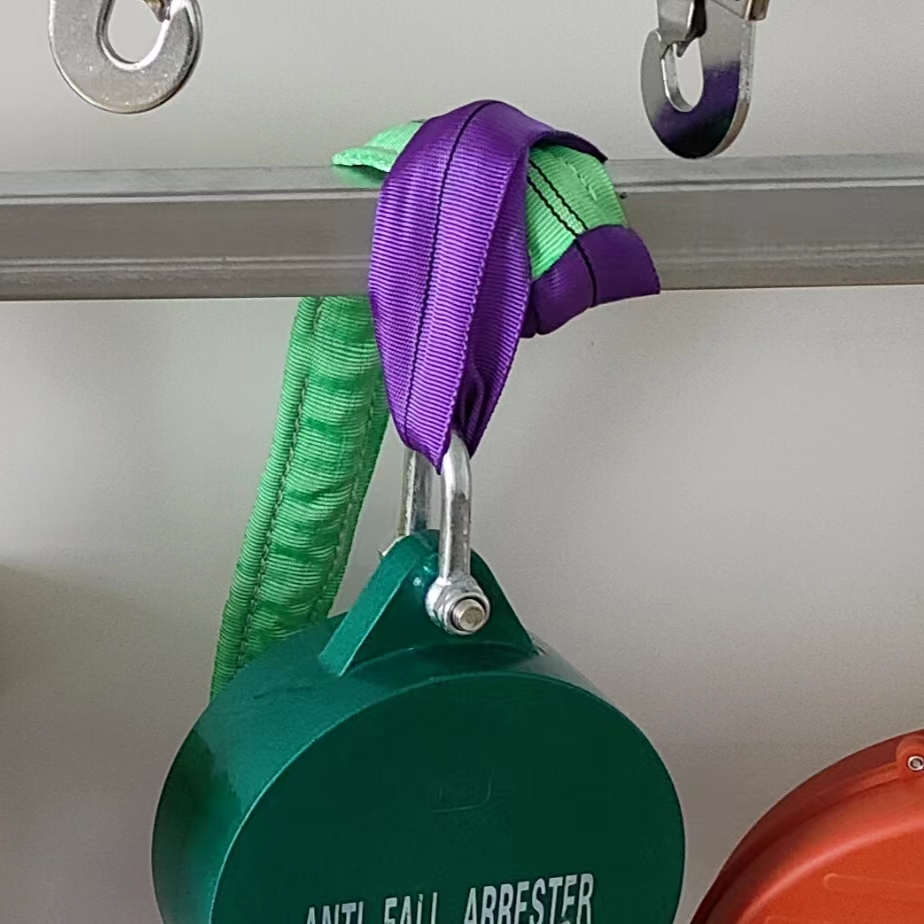

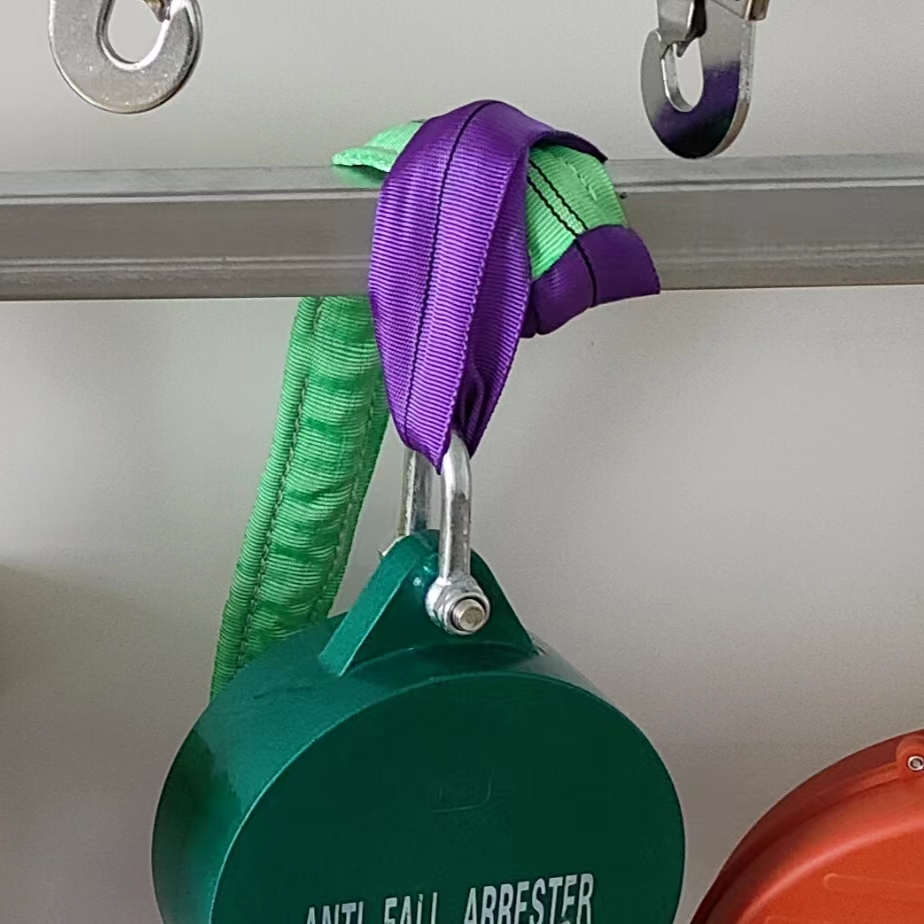

Trustworthiness is underscored by the rigorous safety standards adhered to by full-powered pallet jack manufacturers. Features such as automatic speed reduction during turns, anti-roll-back systems on inclines, and emergency reversing functionalities set industry benchmarks. Furthermore, the ergonomic design considerations, such as adjustable handrails and anti-fatigue platforms, underscore a commitment to operator safety and comfort.

Full-powered pallet jacks also contribute significantly to sustainability efforts within supply chains. Reduced energy consumption, lower emissions, and quieter operations align with green logistics initiatives, crucial for companies aiming to lessen their ecological footprint while adhering to environmental regulations.

In summary, the adoption of full-powered pallet jacks should be considered not just a trend but a strategic investment. The culmination of ergonomic design, cutting-edge technological integration, and stringent safety measures makes these machines indispensable for modern material handling. They not only enhance workforce efficiency but also offer a reliable, sustainable solution that supports the logistical demands of contemporary business environments. Embracing these tools is emblematic of a forward-thinking business ethos that values innovation, operational excellence, and environmental stewardship.