Navigating the complex world of fall protection devices is crucial in ensuring safety at worksites, especially in industries like construction, manufacturing, and maintenance. These industries are fraught with the potential for dangerous mishaps, and as a result, selecting the right fall protection device becomes a matter of life and death. This comprehensive guide offers real-world insights and authoritative advice to help you make informed decisions regarding these life-saving devices.

Imagine a construction worker striding confidently across a rooftop, securely tethered to a state-of-the-art fall protection device. This equipment is not just a regulatory requirement; it is a testament to the company's commitment to safety and the worker's trust in their own security.

Investing in high-quality fall protection is fundamentally an investment in human lives. The experience and expertise of those who design, manufacture, and implement these devices cannot be overemphasized.

Fall protection devices encompass a variety of equipment types, each with its unique application and benefits. Harnesses, lifelines, anchors, and safety nets are just a few examples. Each has been meticulously engineered to meet specific safety standards and to offer maximum protection in applications ranging from residential roofing to skyscraper construction.

Harnesses are often the first line of defense and must be comfortable, adjustable, and durable. They are designed to distribute the force of a fall across the wearer's body, minimizing injury. When considering harnesses, look for certifications from recognized safety organizations such as ANSI (American National Standards Institute) or OSHA (Occupational Safety and Health Administration). These certifications ensure the harness meets rigorous safety standards and has been tested for performance under various conditions.

Lifelines, whether they are vertical or horizontal, offer workers mobility while still ensuring safety. These can be rope-based or cable-based, with self-retracting lifelines providing the flexibility of movement along a line while automatically locking in the event of a fall. Selecting the right lifeline system depends on the working environment and the specific needs of the project. Expert consultation is advisable to configure the best system suitable for the specific hazards present.

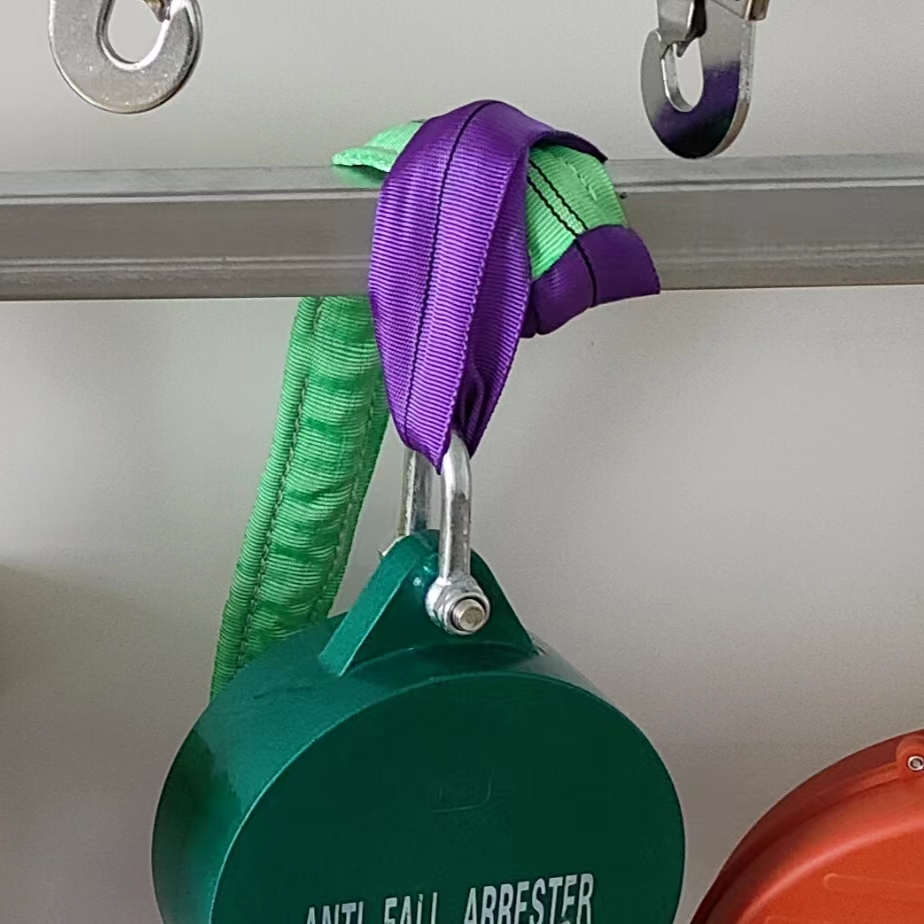

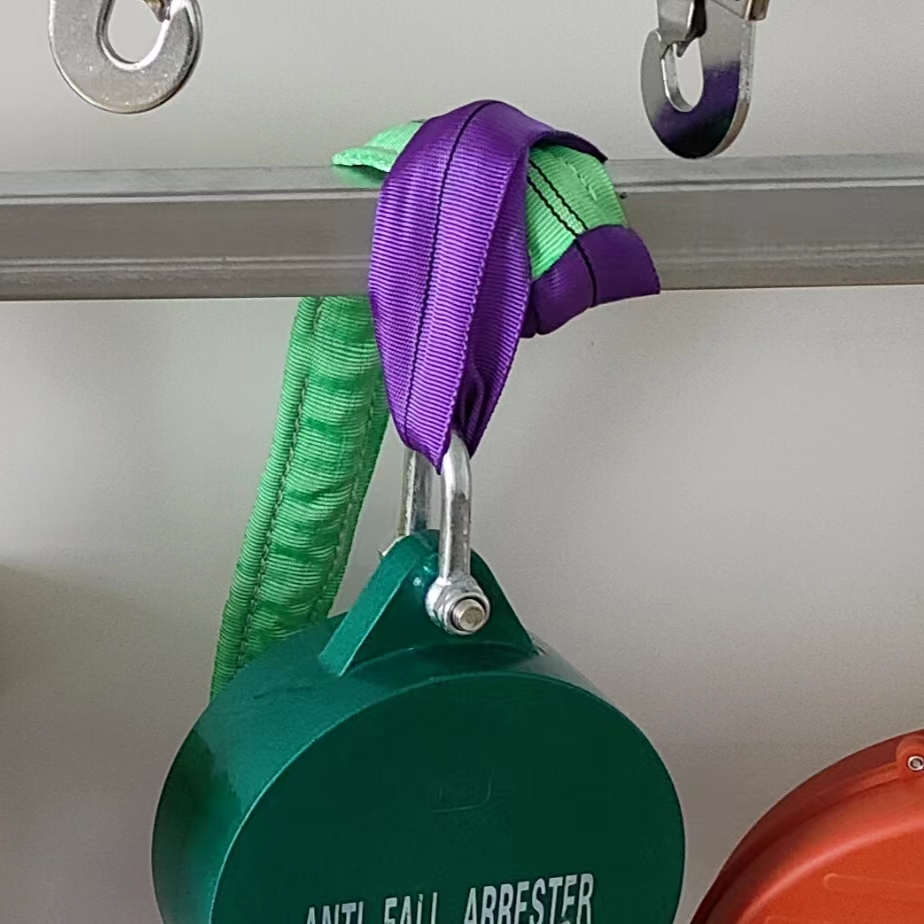

fall protection device

Anchor points, often overlooked, are just as crucial as the harnesses and lines themselves. These points need to be solidly installed and capable of withstanding impacts greater than those expected in normal scenarios. Ensuring that anchor points are properly certified and maintained goes a long way in fortifying the safety of a job site. Professional installation and regular inspection are non-negotiable aspects of their setup.

Safety nets, another essential component, are generally used as collective fall protection measures in large scale projects and in scenarios where installing personal fall arrest systems is not viable. Their strategic placement can catch multiple workers simultaneously, adding a broader layer of safety for large crews. However, for nets to be effective, they must be inspected frequently and maintained rigorously. Their installation should be supervised by experienced personnel who understand the dynamics of fall arrests.

The trustworthiness of a fall protection device is largely determined by the reputation of the manufacturer. Companies that have invested heavily in research and development to improve their products' safety features tend to produce equipment that meets and exceeds safety expectations. Industry leaders often provide comprehensive warranties and customer support, ensuring that their products remain reliable and effective over time.

Purchasing a fall protection device is not merely a transaction; it is an assurance that the equipment is backed by a legacy of safety and innovation. Always seek testimonials or case studies from users who have integrated these systems into their work environments. Their real-world experiences can provide insights that specifications and user manuals alone may not reveal.

Choosing the right fall protection device requires not just an understanding of the product specifications but also an insight into the safety challenges specific to your work environment. Draw upon the expertise of safety consultants and the authoritative knowledge offered by manufacturers to ensure that the equipment will not only meet regulatory requirements but also foster a culture of safety and reliability at your worksite.