The Importance of Electronic Crane Scales in Modern Industries

In today's fast-paced industrial environment, precision and efficiency are paramount. One of the essential tools that has emerged to meet these demands is the electronic crane scale. Designed to streamline the weighing process, these scales have transformed various industries, from construction to manufacturing, by providing accurate weight measurements that are crucial for safety, compliance, and operational efficiency.

An electronic crane scale is a sophisticated device that utilizes electronic sensors to measure the weight of heavy loads suspended from a crane. Unlike traditional mechanical scales, electronic crane scales offer numerous advantages. Their digital displays provide easy-to-read weight measurements, often in real-time, allowing operators to make immediate decisions based on current load conditions. This capability is invaluable in preventing overloads, which can lead to accidents, equipment damage, and potential injury to personnel.

One of the most significant features of electronic crane scales is their accuracy. These scales are engineered to deliver precise measurements, ensuring that operations adhere to safety standards and industry regulations. In sectors such as shipping and logistics, where cargo weight can directly impact shipping costs and safety, accurate weighing is crucial. Electronic crane scales help companies maintain compliance with legal weight limits, avoiding costly fines associated with overweight cargo.

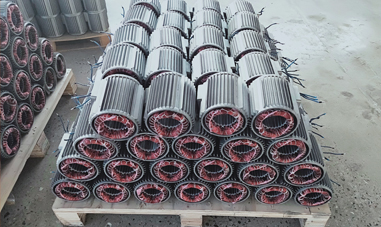

In addition to accuracy, electronic crane scales are designed for durability and ease of use

. Many models are constructed with robust materials that can withstand harsh working environments, such as extreme temperatures, dust, and moisture. This durability ensures that the scales function effectively over extended periods, minimizing the need for frequent replacements and repairs.

Furthermore, modern electronic crane scales often feature advanced connectivity options such as Bluetooth, Wi-Fi, and USB ports. This connectivity allows for seamless integration with inventory management systems, enabling operators to track and record weights automatically. This data collection is crucial for operational analysis, helping companies identify inefficiencies, manage inventory levels, and streamline their supply chain processes.

Another advantage of electronic crane scales is their portability. Many models are lightweight and compact, which means they can be easily moved between different work sites or facilities. This flexibility is particularly beneficial for companies that operate in various locations or across multiple job sites, as it allows them to maintain consistent weighing practices regardless of the environment.

Moreover, user-friendly interfaces make electronic crane scales accessible for operators of varying experience levels. Most models come equipped with simple controls and intuitive displays, which makes training new personnel quick and efficient. Ensuring that all employees can operate weighing equipment correctly is vital for maintaining safety and productivity in any industrial setting.

In conclusion, electronic crane scales are indispensable tools in modern industries that require the accurate weighing of heavy loads. Their precision, durability, and advanced features not only enhance safety and compliance but also improve overall operational efficiency. As industries continue to evolve, the role of technology in facilitating smooth and safe operations will only grow, making electronic crane scales a vital component of any efficient workplace. By investing in these advanced weighing solutions, businesses can ensure they remain competitive while prioritizing safety and operational excellence.