A chain pulley block, especially one with a 20-ton capacity, is an essential tool in many industrial settings. Whether used in warehouses, construction sites, or mechanical shops, selecting the right pulley block can significantly enhance operational efficiency and safety. This article delves into the importance of choosing a 20-ton chain pulley block, drawing from professional insights and real-world applications to ensure your selection is both expert-driven and trustworthy.

When lifting hefty loads, the reliability of your equipment is non-negotiable. Chain pulley blocks are designed to facilitate the manual lifting of heavy items with minimal effort. The 20-ton capacity specifically caters to industries that regularly handle extremely heavy materials. For example, steel fabricators, shipyards, and large-scale manufacturing units often find these indispensable due to their robust capabilities.

One key advantage of a 20-ton chain pulley block is its ability to provide consistent lifting power while maintaining precision and control. Unlike smaller capacity blocks, the 20-ton variant accommodates a wider range of heavy lifting tasks, reducing the need for multiple devices. This versatility not only saves on equipment costs but also minimizes maintenance downtime.

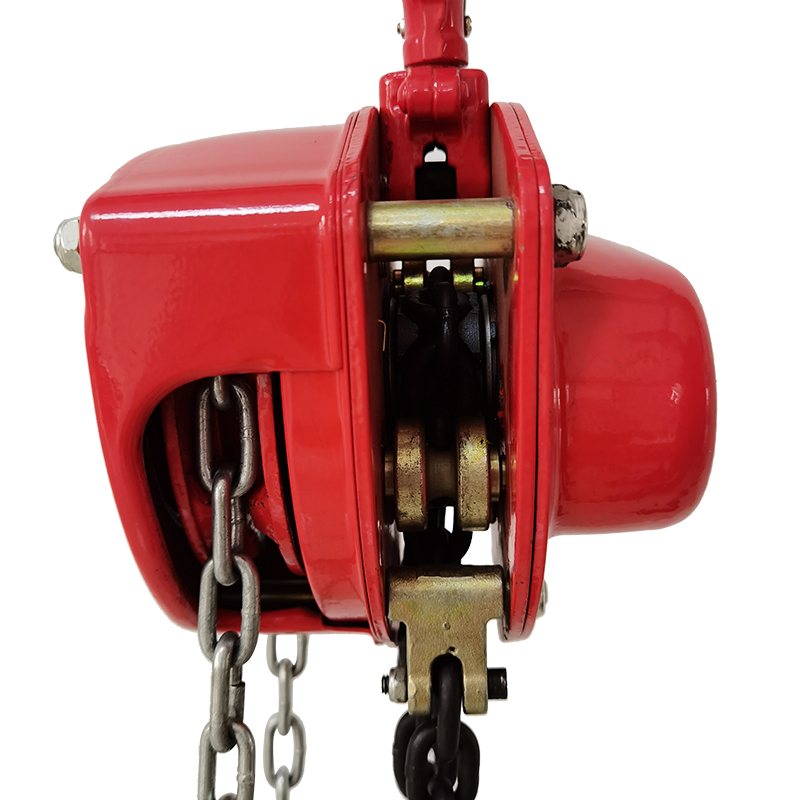

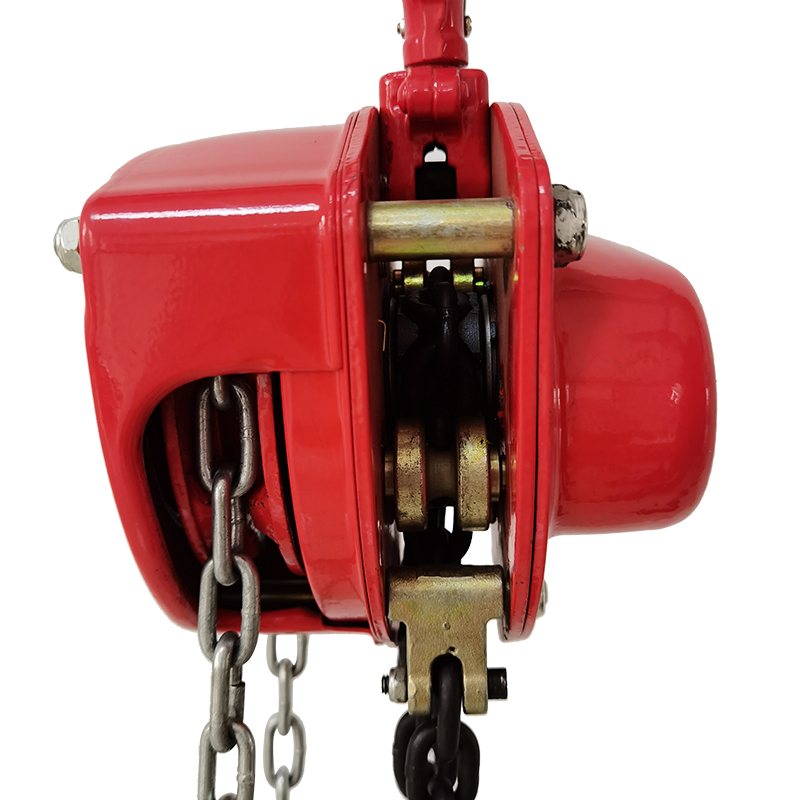

For professionals in the field, the choice of a chain pulley block should be informed by both experience and technical specifications. Expert reviews and case studies have shown that a high-quality 20-ton chain pulley block features durable components, including alloy steel chains and strong hooks designed to endure the strain of lifting up to 20 tons without deformity or risk of failure. Such specifications are pivotal in guaranteeing longevity and reliability, thereby maximizing return on investment.

Safety is another paramount consideration when employing these devices. Advanced models come with features like double-pawl braking systems, overload protection, and refined gear mechanisms, all of which contribute to safer operations. When tackling 20-ton loads, even a minor equipment malfunction can lead to catastrophic outcomes. Thus, investing in a reputable chain pulley block with comprehensive safety features is crucial in maintaining a secure working environment.

chain pulley block 20 ton

From a trustworthiness perspective, certifications and compliance with local and international standards are non-negotiable. Look for products that meet ISO 9001 standards or are certified by recognized bodies such as the American Society of Mechanical Engineers (ASME). These accreditations add a layer of assurance to the device’s quality and safety standards.

In practice, numerous companies have harnessed the power of the 20-ton chain pulley block to streamline their operations. Take, for instance, a case where a construction firm dealing with large structural components reported a 30% increase in efficiency and a significant reduction in labor costs after implementing these pulley blocks into their workflow. Not only did the machinery empower their workforce to handle heavy load tasks more comfortably, but it also improved overall job safety metrics.

It's important to highlight that successful integration of a 20-ton chain pulley block into your operations requires training and regular maintenance checks. Operators must understand the nuances of weight limits, environmental factors, and mechanical checks before operating the devices. Routine inspections should include examining for wear and tear, ensuring that all parts are in alignment, and guaranteeing that moving parts are adequately lubricated.

In conclusion, selecting a 20-ton chain pulley block involves a mix of practical experience and technical knowledge to ensure it meets your heavy lifting needs while upholding safety and operational effectiveness. By choosing a model that balances expertise-driven design, authority through certification, and reliability through exhaustive safety measures, you set your enterprise up for enhanced productivity and reduced risk. As a cornerstone of any effective material handling strategy, these machines prove their worth time and again, solidifying their role as an irreplaceable asset in heavy load management across numerous industries.