Choosing the right chain pulley system for lifting tasks can make a significant difference in efficiency and safety, particularly when dealing with a weight range of around one ton. With countless models and price variations available online, understanding the factors that influence the cost of a 1-ton chain pulley can help buyers make informed decisions. Here's a closer examination of what affects pricing and why these tools are vital in different industrial settings.

Chain pulleys, or hoists, have been staples in manufacturing, construction, and maintenance industries due to their mechanical advantage, allowing heavy loads to be lifted with minimal human effort. These systems are often graded by their lift capacity and durability, impacting their price.

Several key components determine the price of a 1-ton chain pulley

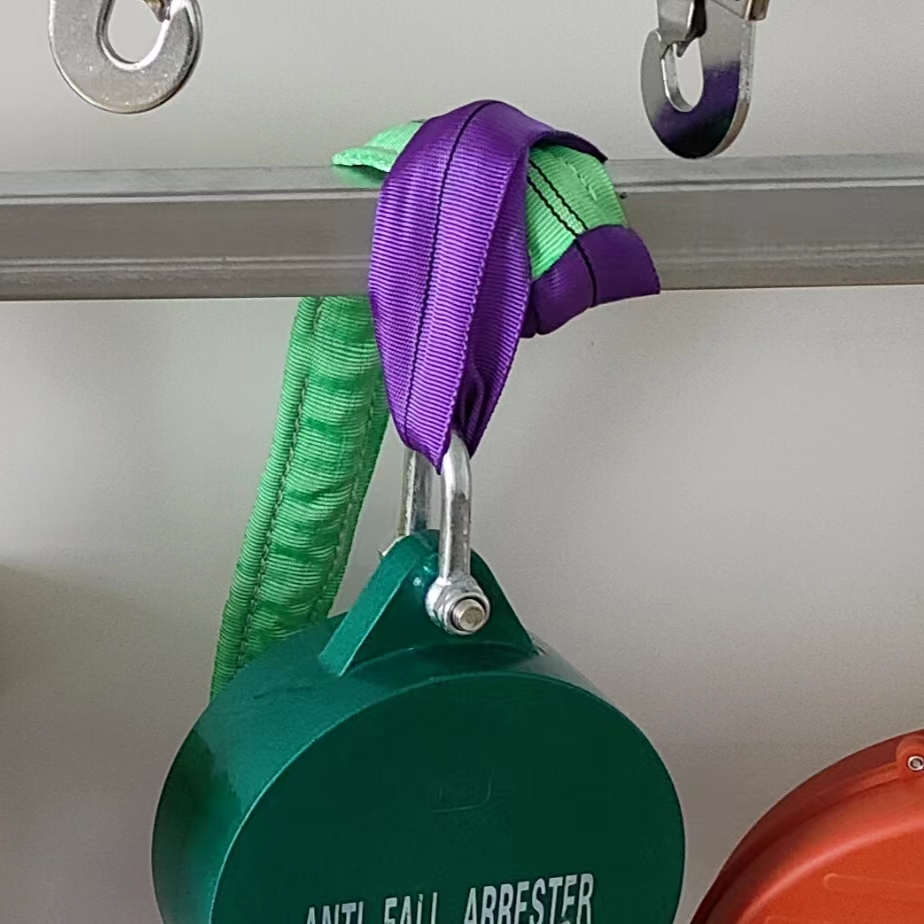

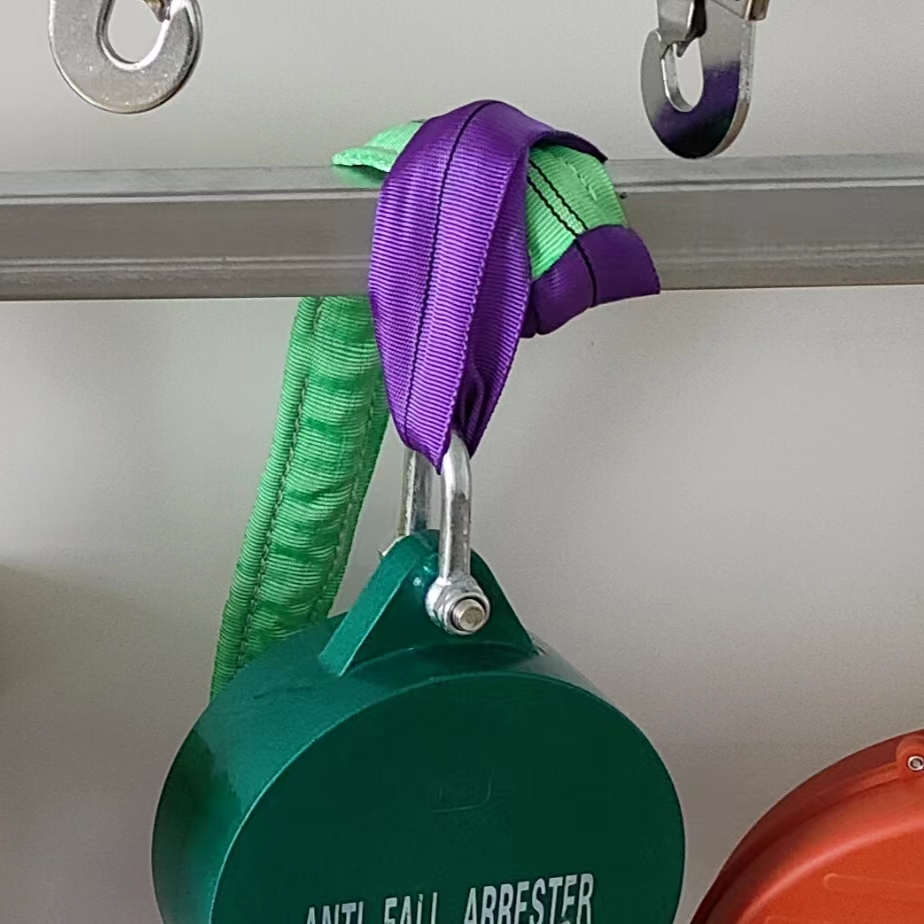

1. Material Quality High-quality materials, such as alloy steel for the chain and forged hooks, ensure durability and safety. Manufacturers producing hoists with these materials can command higher prices due to the reliability and lifespan of their products.

2. Mechanical Advantage Different models may offer varying mechanical ratios that affect ease of operation. A higher mechanical advantage usually translates to a higher cost but results in less effort required to lift heavy loads.

3. Brand Reputation Reputable brands recognized for their rigorous testing and adherence to safety standards often charge premium prices. Their commitment to safety and quality assurance provides peace of mind for users, making the additional cost worthwhile.

4. Advanced Features Some chain pulleys come equipped with additional features such as overload protection, slip clutches, or dual-speed lifting. These enhancements contribute to higher costs but improve functionality and protect against misuse and potential damage.

chain pulley 1 ton price

5. Certification and Compliance Products certified by organizations like ANSI or ASME affirm that they meet rigorous safety standards.

Certification assures buyers of a product’s reliability but may contribute to a higher price tag.

6. Customization Options Certain projects may require hoists with specific modifications, such as custom lift lengths or specialized hooks. Customized solutions often drive prices higher due to the specialized manufacturing processes involved.

Understanding how these factors influence the price of a chain pulley helps buyers determine what level of investment aligns with their needs and usage frequency. For frequent, heavy-duty use, investing in a premium model could mean fewer maintenance issues and longer operational life, justifying the cost.

Real-world experience shows that opting for a cheaper, lower-quality hoist might save money upfront but can lead to increased maintenance costs and potential safety hazards over time. For instance, a construction company utilizing a sub-standard hoist might encounter unexpected breakdowns, delaying projects and increasing downtime costs, not to mention the elevated risk of workplace accidents.

Expertise in selecting the right hoist also involves understanding operational environments. An indoor facility with controlled conditions might not need corrosion-resistant materials, unlike an outdoor setting, where exposure to elements necessitates stainless steel components to prevent rust.

The authoritativeness of a brand, backed by certifications and compliance with industry standards, plays a crucial role in establishing trust. Companies like CM, Yale, and Harrington have built decades-long legacies of reliable products. Purchasing from these companies provides assurance supported by countless testimonials and user reviews.

In conclusion, while prices for a 1-ton chain pulley vary significantly, understanding the integral components that justify these differences empowers buyers. Investing in a high-quality chain pulley system is not just about a financial transaction but ensuring safety, efficiency, and longevity in lifting operations. Ultimately, achieving a balance between price, quality, and specific use-case requirements leads to the most effective purchase decision. Engaging with reputable sellers and seeking expert advice further enhances decision-making, aligning operational goals with reliable equipment solutions.