Selecting the right 2-ton air chain hoist is crucial for businesses aiming to enhance their operational efficiency and ensure workplace safety. A 2-ton air chain hoist, designed specifically for heavy-duty lifting tasks, forms the backbone of industries such as construction, manufacturing, and maintenance. Combining user testimony with industry best practices, this article delves into the essential features and considerations that make a high-quality 2-ton air chain hoist indispensable.

When evaluating a 2-ton air chain hoist, safety should always be the primary concern. It is imperative to opt for models equipped with reliable braking systems. For instance, many industry veterans recommend hoists with load-limiting devices and emergency stop features, which offer immediate responsiveness and control, reducing the likelihood of accidents. Additionally, the hoist must comply with international safety standards, which not only ensure worker safety but also protect the company from potential liabilities.

The durability of the hoist is another significant factor. For businesses operating in demanding environments, selecting a hoist with a robust build is essential. This includes features such as heat-treated, heavy-duty housing and corrosion-resistant components which enhance the lifespan of the equipment. A balanced case study highlighted in industry journals reveals that investing in durable hoists can reduce downtime significantly, thereby increasing productivity and reducing overhead costs.

Ease of use is equally important. Modern 2-ton air chain hoists come with ergonomic designs that minimize the physical strain on operators. This includes intuitive controls that can be operated effortlessly, allowing for precise positioning and smooth operation. Real-world feedback from a manufacturing plant known for its rigorous lifting operations noted substantial improvements in operational efficiency and employee satisfaction following the adoption of hoists with user-friendly interfaces.

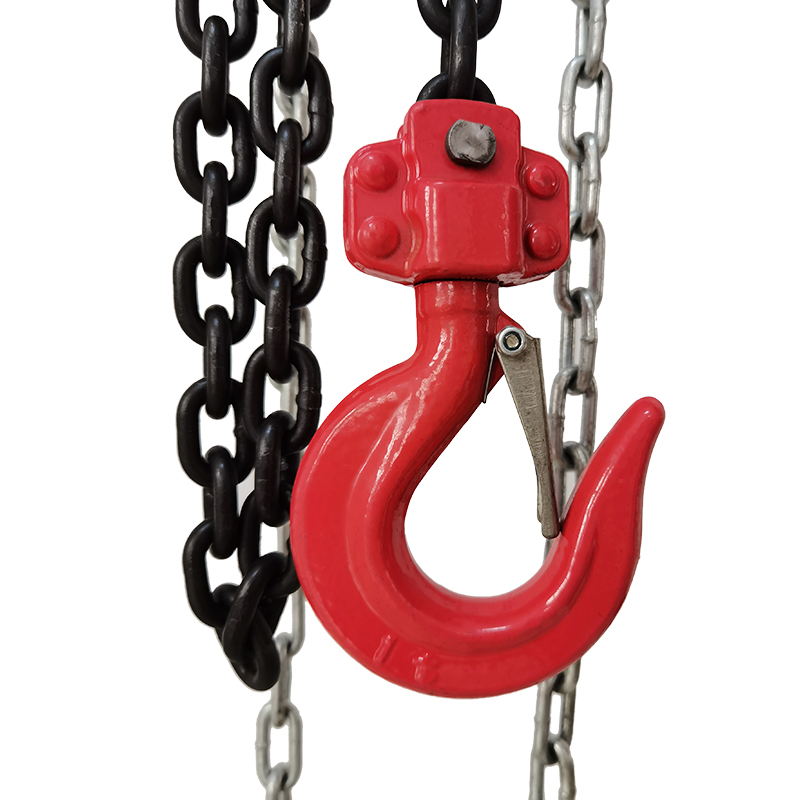

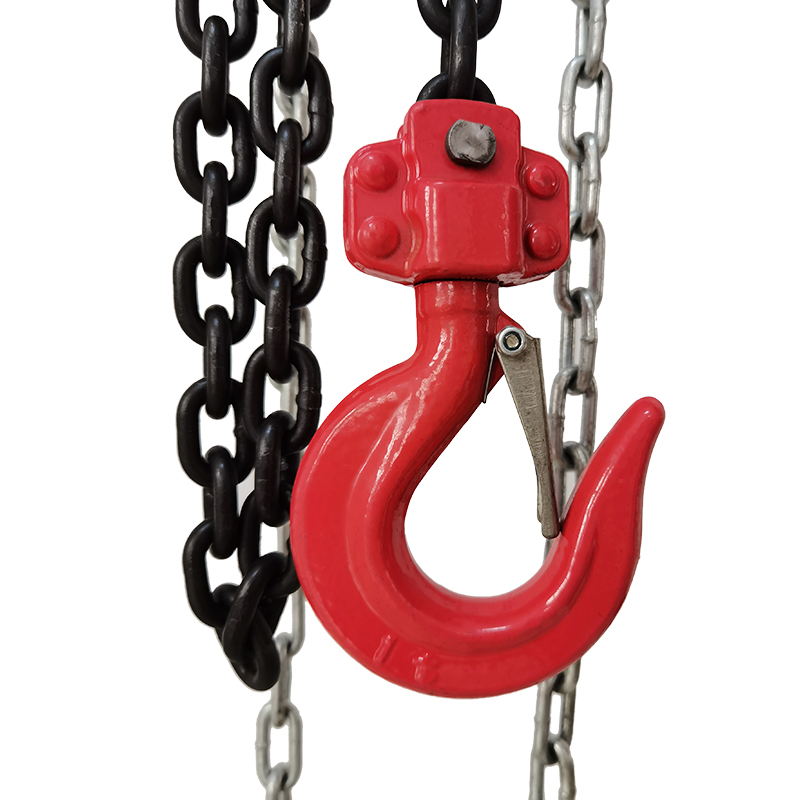

2 ton air chain hoist

Another critical aspect is the lifting speed. Selecting a hoist with variable speed controls can enhance operational flexibility, allowing businesses to tailor lifting speeds to specific tasks. As emphasized by a leading industrial equipment expert, variable speed control minimizes the risk of load damage and enhances the precision of load placement, which is crucial in delicate manufacturing processes.

The power source and air consumption of the hoist are also key determinants of operational efficiency. A reputable analysis of industrial hoists recommends selecting models designed for energy efficiency. Hoists with optimized air consumption not only reduce energy costs but also reflect a commitment to sustainable practices, aligning with corporate environmental responsibility goals.

Support and maintenance are often overlooked yet vital elements. Choosing a supplier that offers comprehensive after-sales support, including parts availability and technical assistance, is advisable. Testimonials from long-term users consistently praise brands that provide robust support networks, underscoring the significant reduction in operational disruptions when issues are promptly addressed.

In conclusion,

a 2-ton air chain hoist's value extends beyond its lifting capacity. By prioritizing safety, durability, ease of use, speed variability, energy efficiency, and support, businesses can make informed decisions that bolster their operational workflows. Trusted industry resources advocate thorough evaluation and possibly hands-on testing to ensure the selected hoist meets and exceeds the specific needs of the application. This careful consideration of all aspects of the hoist not only safeguards investments but also enhances overall workplace productivity and safety.