Understanding the 1% Ton Chain Block A Crucial Tool in Material Handling

In the world of material handling and construction, efficiency and safety are paramount. One of the essential tools that enhance these factors is the 1% ton chain block. This device plays a significant role in lifting heavy loads, making it an indispensable asset in various industrial sectors.

What is a Chain Block?

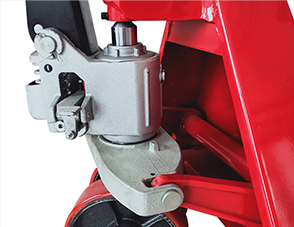

A chain block, also known as a chain hoist, is a mechanical device that uses a chain and a pulley system for lifting heavy objects. The 1% ton specification indicates that the block is capable of lifting loads of up to one ton (1000 kg) with ease. Chain blocks are typically constructed from high-strength steel and designed to withstand significant wear and tear. They comprise several key components, including the hoisting mechanism, load chain, hooks, and a casing that protects the internal components. The operation of a chain block involves pulling on the hand chain, which in turn rotates the hoist’s gears, raising or lowering the load attached to the overhead hooks.

Applications of 1% Ton Chain Blocks

The versatility of the 1% ton chain block makes it suitable for a wide range of applications across various sectors. In construction, they are commonly used for lifting steel beams, concrete blocks, and other heavy materials. Their ability to lift substantial loads safely allows builders to construct frameworks efficiently and securely.

In manufacturing, chain blocks are instrumental in assembly lines, where they facilitate the movement of heavy parts and components. They also play a vital role in warehouses, aiding in the loading and unloading of goods. In maritime settings, chain blocks are often employed to lift cargo containers and equipment on ships and docks.

Furthermore, in maintenance and repair operations, these hoists are invaluable for servicing heavy machinery and vehicles. By providing an accessible means to lift and maneuver such equipment, they streamline processes and enhance the productivity of workers.

Safety Considerations

When using a 1% ton chain block, safety must be the foremost consideration. These devices are designed for heavy lifting, but improper use can lead to accidents and injuries. Operators must be adequately trained in the correct methods of using chain blocks, including understanding the weight limits and load balancing.

Moreover, regular maintenance of chain blocks is crucial. This involves inspecting the chain for wear, ensuring that the hoist mechanism functions correctly, and checking the integrity of the hooks and casing. By adhering to these safety and maintenance guidelines, users can prolong the life of the equipment and avoid mishaps.

Advantages of Using Chain Blocks

Several advantages make the 1% ton chain block a preferred choice in lifting applications. Firstly, its simplicity in design allows for ease of use. Operators can quickly set up and operate the chain block, making it ideal for environments where speed is essential.

Secondly, chain blocks are relatively lightweight compared to other lifting equipment, such as cranes or forklifts. This portability enables workers to use them in areas with limited space or where traditional lifting equipment cannot access.

Finally, chain blocks are cost-effective. They offer a high lifting capacity without the need for significant investment in more complex machinery. This affordability does not compromise their effectiveness, making them a reliable option for businesses of all sizes.

Conclusion

The 1% ton chain block is a fundamental tool in the domain of material handling and construction. Its ability to lift heavy loads safely and efficiently makes it ideal for various applications across multiple industries. By understanding its functionalities, advantages, and safety protocols, users can harness the full potential of this powerful lifting device, enhancing productivity while ensuring a safe working environment. Whether in construction, manufacturing, or maintenance, the 1% ton chain block remains an essential asset in modern operations.