Choosing the right lifting equipment is crucial for efficiency and safety in various industrial and construction tasks. The 1.5-ton lever block stands out as a versatile and reliable tool among the different devices available. With years of hands-on experience and expertise in the field, understanding the nuances of this equipment can significantly boost your operational efficiency and safety standards.

A lever block, often synonymous with a chain hoist or come-along, harnesses the power of a lever to lift or lower heavy loads. The 1.5-ton capacity lever block is particularly popular due to its optimal balance between load capability and portability. This blend makes it an excellent choice for medium-duty applications across multiple industries, including construction, manufacturing, and logistics.

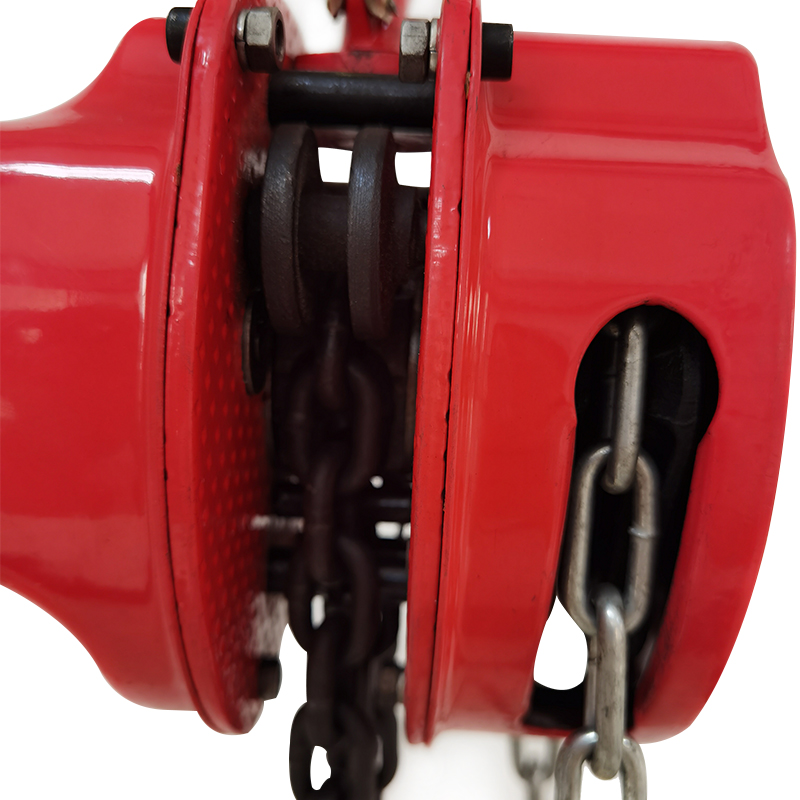

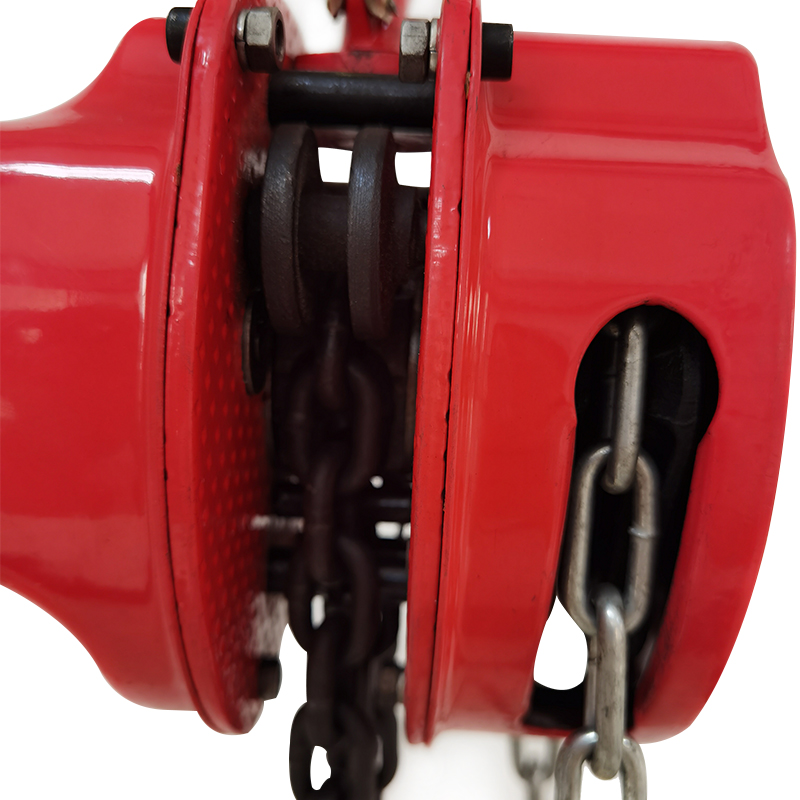

When it comes to the expertise surrounding the 1.5-ton lever block, several key features are noteworthy. The tool typically features a robust chain made from high-grade alloy steel. This material choice is crucial because it provides the needed strength to support substantial weights while ensuring durability and longevity in rigorous working conditions. Furthermore, these chains undergo heat treatment processes to bolster their strength and resilience against wear and environmental damage.

Another technical aspect that underscores the reliability of 1.5-ton lever blocks is the precision-engineered gear system. This system ensures smooth operation and minimizes the manual effort required to lift loads. It also plays a vital role in load control, preventing the load from slipping or free-falling, which can be a significant safety hazard. Moreover, the inclusion of mechanical braking systems in some models enhances the control and safety of lifting operations by allowing users to secure the load in any position.

From an authority and trustworthiness perspective, selecting a lever block manufactured by a reputable company is paramount. Brands with extensive track records in producing lifting equipment typically adhere to stringent quality and safety standards. These manufacturers often obtain certifications from relevant industry bodies, such as ISO or ANSI, which further validates the reliability and safety of the lever block. This adherence to quality standards is essential not just for safety but for compliance with legal requirements in various jurisdictions, which mandate specific certifications for lifting equipment.

1.5ton lever block

Practical experience also suggests the importance of regular maintenance and inspection protocols to ensure the continued safe use of a 1.

5-ton lever block. Routine checks should include inspecting the chain for any signs of wear or damage, verifying the functionality of the braking system, and ensuring that all components are free from rust and corrosion. Such preventive measures help extend the lifespan of the equipment and maintain its operational efficiency.

In addition to technical specifications, user experience is a crucial factor in the successful deployment of a 1.5-ton lever block. Ease of use is often reported as a top benefit, as the lever mechanism requires minimal training for effective operation. The compact size and lightweight design further contribute to its appeal, allowing workers to easily transport and set up the lever block in different locations or job sites.

Industries that frequently rely on 1.5-ton lever blocks, such as construction and manufacturing, consistently report significant productivity improvements. These blocks enable quicker setting up of temporary lifting solutions, reduce the need for extensive rigging setups, and permit operations in confined spaces where larger cranes cannot reach. The versatility of application—from horizontal pulling to vertical lifting—also makes it a go-to tool in diverse settings, reinforcing its value proposition.

In summary, the 1.5-ton lever block is a cornerstone tool in many industrial applications. Its blend of technical reliability, ease of use, and the backing of reputable manufacturers makes it a trusted choice for professionals seeking safe and efficient lifting solutions. By understanding both the technical underpinnings and practical applications of this equipment, users can maximize safety, compliance, and operational effectiveness. Selecting a high-quality lever block, keeping it well-maintained, and ensuring user expertise are all essential factors in leveraging this equipment's full potential.